Understanding Primer Printing: A Comprehensive Guide

What is Primer Printing?

Primer printing refers to the specialized printing process that involves applying a primer coating on surfaces before the actual print. This technique ensures optimal ink adhesion, vibrant colors, and longevity of printed materials. In this guide, we will delve deep into the world of primer printing, its applications, benefits, and best practices.

The Importance of Primer in Printing

Using a primer in printing serves multiple purposes that bolster the quality and durability of printed products. Here's why primer printing is crucial:

- Enhanced Ink Adhesion: Primers create a better surface for inks to cling onto, resulting in a more durable print.

- Color Vibrancy: A primer helps in achieving brighter colors and prevents them from fading quickly, enhancing the visual appeal.

- Surface Uniformity: Primers help in smoothing out the surface, providing a uniform area for even ink distribution.

- Weather Resistance: Certain primers can protect prints from environmental factors, making them suitable for outdoor applications.

Applications of Primer Printing

The versatility of primer printing allows it to be used in various industries. Here are some notable applications:

1. Packaging Industry

In the packaging sector, primer printing is essential for creating high-quality labels and packages that stand out on shelves. Products that utilize this printing method include:

- Food and Beverage Packaging

- Cosmetics and Skincare Products

- Pharmaceuticals

- Consumer Goods

2. Electronics

For electronics, primer printing ensures that labels and instructions remain readable and durable. This is important for:

- Product Labels

- Warning and Instruction Labels

- Branding and Identification Labels

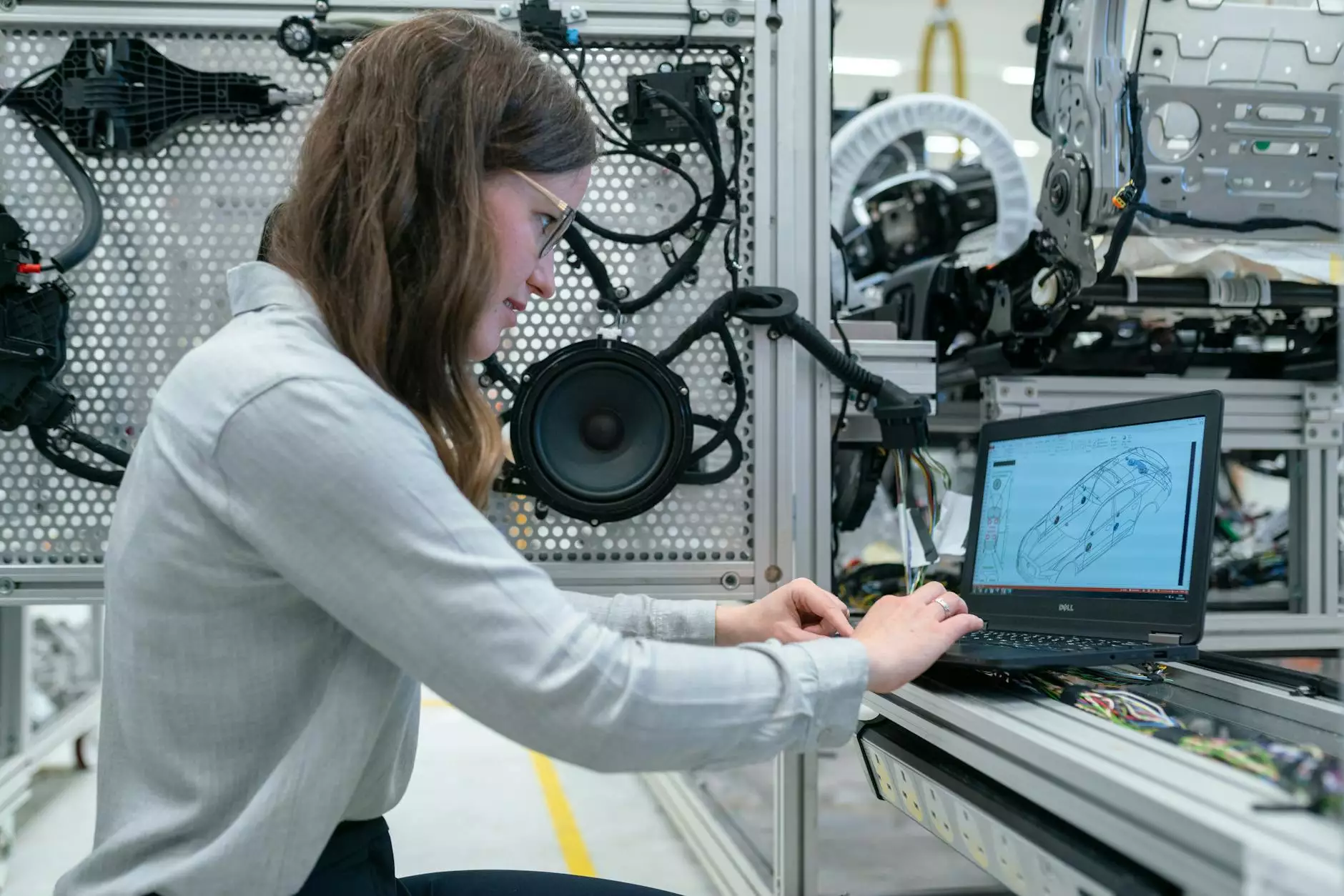

3. Automotive Industry

Automotive parts and accessories benefit greatly from primer printing, ensuring that labels withstand the test of time and exposure. Applications include:

- Parts Identification Labels

- Safety and Compliance Labels

- Branding Material for Automotive Products

Benefits of Utilizing Primer Printing

Choosing primer printing for your projects comes with numerous advantages:

- Cost-Effectiveness: Although it may seem like an additional step, effective primer printing can reduce overall costs by minimizing wastage and ensuring high-quality end products.

- Durability: Primers protect printed materials from wear and tear, ensuring a longer lifespan of the final product.

- Reduced Ink Smudging: The right primer can significantly reduce the risk of smudging, making your prints look professional and appealing.

- Customizability: Different types of primers and processes allow for a wide variety of finishes and textures, making it easier to achieve specific design goals.

Choosing the Right Primer for Printing

The choice of primer is critical for achieving optimal results. Here are some factors to consider:

- Surface Material: Different surfaces (plastic, metal, paper) may require specific primers for best adhesion and finish.

- Application Method: Consider whether you'll be using digital, flexographic, or offset printing methods, as this may influence your primer choice.

- Environmental Conditions: If the printed material will be exposed to harsh conditions, select a primer designed for outdoor use.

- Compliance Standards: Ensure that the primer meets necessary industry standards and regulations, particularly in sectors like food and pharmaceuticals.

Best Practices for Primer Printing

To maximize the benefits of primer printing, follow these best practices:

1. Testing

Always conduct test prints with your selected primers to check for adhesion, color fidelity, and overall quality before proceeding with large runs.

2. Clean Surfaces

Ensure that all surfaces are thoroughly cleaned and free from dust, grease, and other contaminants that might affect adhesion.

3. Proper Application Techniques

Follow manufacturer guidelines for applying primers. Whether spraying or brushing, consistency is key for even coverage.

4. Allow Proper Curing Time

Each primer has a specific curing time that allows it to bond effectively with the surface before actual printing can begin.

5. Train Your Team

Ensure that everyone involved in the printing process understands the importance of primer printing and knows how to apply it effectively.

Case Studies: Successful Primer Printing Implementations

Real-world examples highlight the efficacy of primer printing in various industries:

1. A Food Packaging Company

A food packaging business implemented primer printing to enhance the quality of their labels and packaging. By doing so, they achieved improved color retention and resistance to moisture, which significantly reduced complaints about fading labels over time.

2. An Electronics Manufacturer

An electronics manufacturer utilized primer printing for their product labels. The result was a notable increase in customer satisfaction due to clearer, more durable labels that stood the test of time, even under tough conditions.

The Future of Primer Printing

As technology continues to evolve, the landscape of primer printing is set to change. Innovations such as eco-friendly primers and digital printing technologies will usher in a new era of sustainability and efficiency in the printing industry.

Conclusion

In conclusion, primer printing is a vital process that enhances the quality and durability of printed materials across various industries. By understanding its applications and benefits, businesses can leverage this technique to improve their products and services. At Durafast Label, we are committed to providing high-quality printing solutions, including primer printing, that meet your specific needs.

FAQs about Primer Printing

1. What materials can benefit from primer printing?

Primer printing is beneficial for a wide range of materials, including paper, plastic, metal, and more, enhancing ink adhesion and overall print quality.

2. Can primer printing help with outdoor applications?

Yes, certain primers are specifically formulated for outdoor use, providing excellent weather resistance and longevity for printed materials exposed to the elements.

3. How can I ensure the best results from my primer printing?

Conduct thorough testing, choose the appropriate primers for your substrate, and adhere to best practices in application for optimal results.